machinery, and our focus on advanced technology and

excellent customer service

59 Year Experience

With over 59 years of experience in the field of industrial manufacturing, we guarantee the best quality and products.

Professional

Team

With a professional team of steelers, we are all experienced and highly skilled in manufacturing.

Sales Dedication

We Believe that every sale is a partnership, and we are committed to delivering value and results that go beyond the transaction.

Customer

Relation

We at TME always close to understand the customer expectation and try to bridge the relation between the supplier and the customer.

59 Year Experience

With over 59 years of experience in the field of industrial manufacturing, we guarantee the best quality and products.

Professional

Team

With a professional team of steelers, we are all experienced and highly skilled in manufacturing.

Sales Dedication

We Believe that every sale is a partnership, and we are committed to delivering value and results that go beyond the transaction.

Customer

Relation

We at TME always close to understand the customer expectation and try to bridge the relation between the supplier and the customer.

Peco InspX is a leading provider of inspection systems for the food, beverage, and life science industries. Headquartered in Silicon Valley, California, we combine.

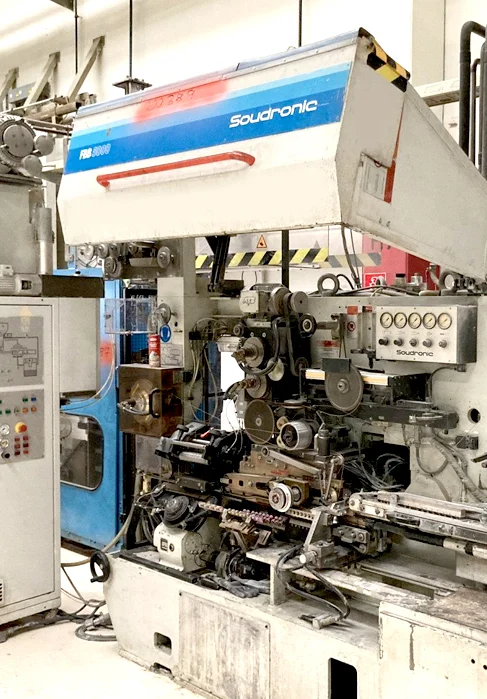

For some years now Soudronic has championed the claim of steel tinplate to be one of the most economical, environment-friendly and sustainable forms of.

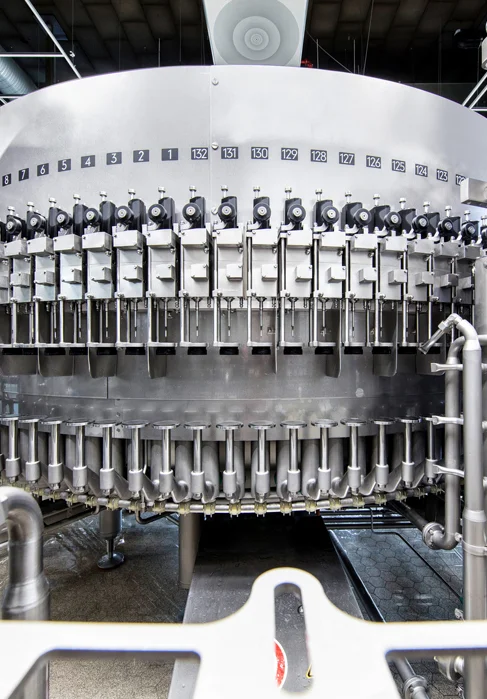

As an international manufacturer of filling and packaging equipment for the beverage, food, and non-food sectors KHS GmbH holds a leading position within the.

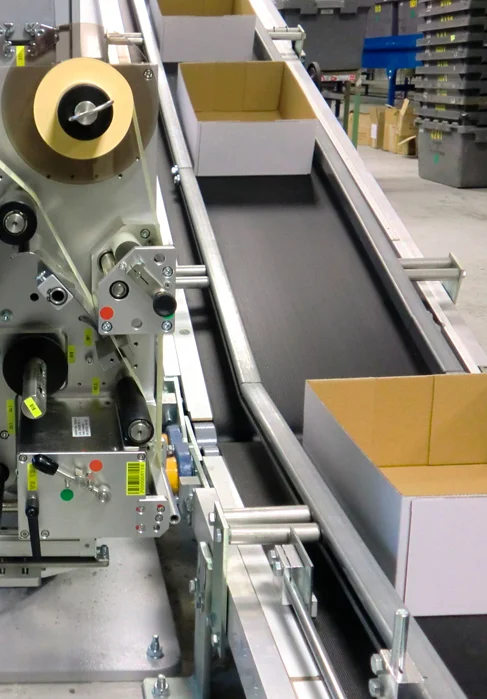

Today, we are a leading supplier of fully integrated labeling systems, providing companies with a highly efficient and reliable interface between production and logistics.

Choosing the right date coding printer depends on several factors, including your specific needs, the type of products you are working with, production volume, and budget considerations.

1.Type of Printing Technology:

•Choose between inkjet, laser, or thermal transfer printing based on your specific needs. Each technology has its advantages and is suitable for different applications.

2.Printing Substrates:

•Consider the variety of materials and surfaces your products are packaged in. Ensure the printer is compatible with different substrates such as paper, plastic, metal, or glass.

3.Print Resolution and Quality:

•Evaluate the print resolution capabilities to ensure the printer can produce high- quality, readable codes, especially if you need to include small characters or intricate details.

4.Production Speed:

•Assess the speed of your production line. Choose a printer that can keep up with your production volume without causing bottlenecks.

Packaging machines are used to package products or components. This product area includes equipment that forms, fills, seals, wraps, cleans, and packages at different levels of automation. Packaging machines also include related machinery for sorting, counting, and accumulating.

The purpose of a packaging machine is to automate the process of enclosing, protecting, and presenting products for distribution, storage, sale, and use. These machines are designed to streamline the packaging process, improve efficiency, and ensure consistency in the packaging of goods

Techno Middle East is on of the oldest distributors in Videojet , operating since 1980’s with experienced engineers in all over gulf countries .Techno Middle East is not only the distributor for Videojet , they are also partners with the leading companies such as KHS , Filtec , Logopak, Soundronics, Taptone , Ferrum, volpak , alimac , Eaton , peco .

Metal detectors are vital for ensuring the safety of consumers. In industries such as food processing and pharmaceuticals, the presence of metal contaminants can pose serious health risks. Metal detection helps identify and eliminate products that may contain metal fragments.

X-ray machines provide detailed images of the product, allowing for comprehensive inspection of not only metal contaminants but also other foreign objects. This is especially important in ensuring product quality and safety.

Fill level monitoring ensures that products are filled to the correct level within packaging. This is crucial for maintaining consistent product quality and meeting customer expectations.

A can seamer is a machine used to seal the lid to the can body. The lid or “end” is usually tinplated steel (food) or aluminum (drinks) while the body can be of metal (such as cans for beverages and soups), paperboard (whisky cans) or plastic.